We are a SWaM company who’s founder is a degreed Urban Forester, ISA Certified Arborist and MD Licensed Tree Expert. Flexi-Pave is our flagship product and is made of recycled passenger tires. Read on to see how this unique paving material can solve many of today’s stormwater, tree preservation and urban infrastructure challenges.

Flexi-Pave is a porous, non-cracking, insulating, and flexible construction material that can be used for a variety of applications. This revolutionary product is environmentally friendly and composed in part from recycled waste tires. It is mixed directly on the installation site and cures in just 24 hours. The result is extremely porous, heavy duty, and dynamic in its physical nature. It is designed for low speed applications with pedestrian and vehicular use, and bonds without trouble to adjacent construction materials. The pervious composition of Flexi-Pave also allows vast amounts of water to flow through which makes it the perfect solution for urban storm water management problems.

Total Square Footage Installed To Date

Total Number of Flexi-Pave Installations

Number of Tires Recycled

- Nominal 3/8 inch (8mm) wire free SBR recycled tire granule

- Nominal 3/8 to 1/2 inch size aggregate rock

- Flexi-Pave’s proprietary sole source binding agent

Flexi-Pave uses a 50 percent ratio of stone and recycled tires. We mix Flexi-Pave on-site with a urethane binding agent and install it as a single monolithic pour. The resulting mixture has the capacity to bind with wood, steel, concrete, aluminum, compacted aggregate, enamel tile, or fiberglass. Furthermore, it is resistant to transmission fluid, brake fluid, gasoline/diesel, hydraulic fluid, salt water, chlorine, ozone, bromine, muriatic acid, and magnesium chloride. These properties make Flexi-Pave unique among surfacing and porous pavement solutions.

- Flexible: will not crack even with root intrusion

- Extremely Porous: allows for ground water recharge and storm water management (BMP’s), 2,000 gallons per square foot/per hour!

- Dynamic in physical form: heavy objects do not leave indentations when removed, 70,000 PSF compressive strength

- Diffuses water force: has erosion control uses (e.g., Embankments, Swales, etc.)

- Impact absorbing surface: injury reduction to joggers and walkers, meets ASTM six foot fall criteria

- Slip resistant: exceeds ADA guidelines, reduces slip, fall and tripping hazards

- Resistant to freeze/thaw: reduction of operation and maintenance costs such as repairing potholes

- Dissipates mechanical shock: resistant to snow plow damage

- Cold weather benefits: in addition to being freeze/thaw and snow plow resistant, use of Flexi-Pave can result in a 50-75% reduction in snow melting materials, and it can be installed with Warmzone Radiant Heating

- Non-flammable: does not burn without the use of an accelerant

- Non-toxic: can be installed near bodies of open water or wetlands, filters out phosphates and nitrates by up to 80%.

Environmental Considerations

The dynamic Flexi-Pave material is the perfect solution whether you are looking to preserve natural resources within an urban environment, or building near delicate ecosystems. Flexi-Pave is highly porous, promoting groundwater recharge at the rate of 2,000 gallons per square foot, per hour. This leads to healthier tree growth and a solid root base enhanced by natural water and air reaching the roots. Furthermore, Flexi-Pave removes nutrient loading associated with storm water runoff (reducing dissolved nitrates and phosphates entering into the groundwater). In addition to the numerous benefits Flexi-Pave provides after installation, the product is also made from recycled tires. 50% of the content of the mixed material is comprised of rubber granulate equating to 1/3 of a tire per square foot. By using Flexi-Pave on your site you’ll be removing tires from landfills and using them to create low maintenance and long lasting solutions for your environmental challenges.

LEED Qualifications

Contributor to 6 of 7 categories:

- SSc6.1 Stormwater Design, Quantity Control (1+ point) – applies to landscaping and water usage

- SSc6.2 Stormwater Design, Quality Control (1+ point)

- MRc4.1/4.2 Recycled Content, 10%/20%/30% (1-2+ points) – up to 2 points are awarded to materials which are recyclable, or use recycled materials in their infrastructure

- MRc5.1/5.2 Regional Materials, 10%/20%/30% (1-2+ points) – this category can earn 1 point if 20% of all materials used are manufactured within a 500 mile radius of the project, and 2 points if half of the materials are.

- IDc1 Innovation in Design (1+ point): this category encourages designers to use new and creative construction approaches, in which flexi-pave may play a role.

Environmental Testing

Is the finished Flexi-Pave product flammable? NO

Tire chips were tested in accordance with the Federal Hazardous Substance Act (16 CFR 1500.44) to determine whether tire material would be considered flammable (a material is considered flammable if it ignites and burns with a self-sustained flame at a rate greater than 0.1 inches per second along its major axis). Test results confirmed that scrap tire material is considered a non-flammable material.

Does Flexi-Pave cause water pollution? NO

After a 5 year field study of the water quality effects of tire shreds placed above the water table, Dana N. Humphrey, Ph.D., P.E., Professor of Civil Engineering, University of Maine concluded in a report dated 1993-1997 that tire shreds had a negligible impact on water quality for the near neutral ph conditions.

Is Flexi-Pave harmful to humans? NO

Numerous studies performed by the EPA and others prove that Flexi-Pave does not cause harm to humans. Click here to see the studies.

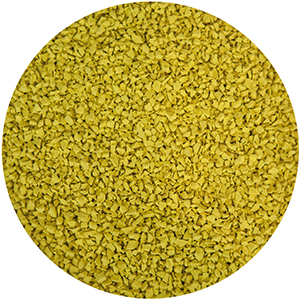

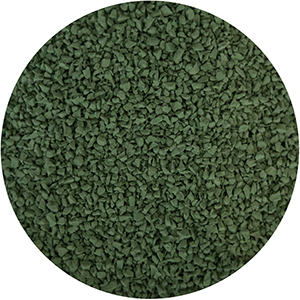

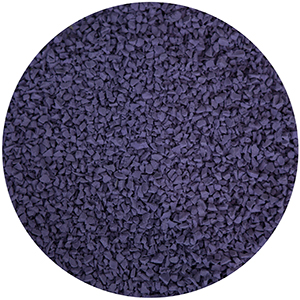

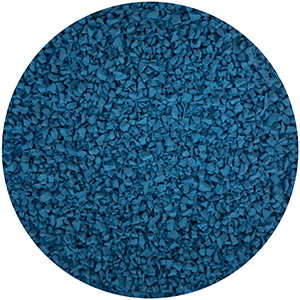

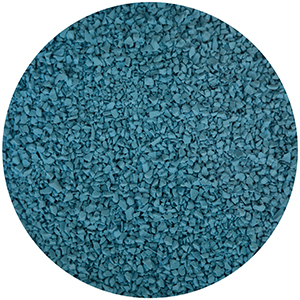

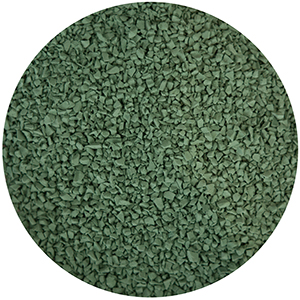

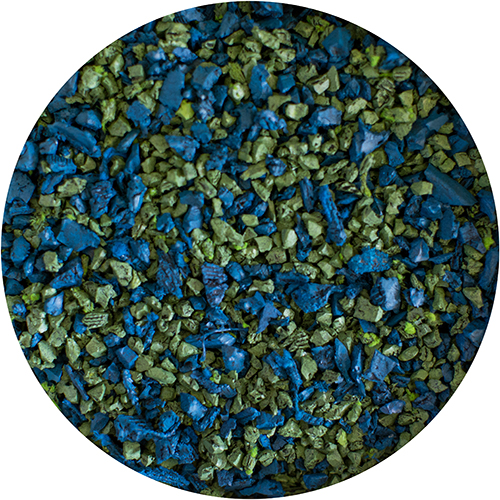

Colors

ALL RUBBER COLORS

P2000, PX2000

ALL STONE COLORS

AS2000

Background

Before establishing Capitol Flexi-Pave we spent years designing new ways to preserve trees in challenging urban settings. Naturally we were invested in learning about paving solutions which could potentially solve the environmental obstacles we faced on our job sites. There were porous concrete and rubber pavements, but those options suffered from limitations such as warping in extreme weather and significant maintenance requirements. When we encountered Flexi-Pave and learned about its resilience, adaptability, and amazing porosity we were sold. It was a product that could meet real world demands for both quality of construction and preservation of natural resources. Shortly thereafter we became the District of Columbia’s certified installer of Flexi-Pave. We have since expanded and presently operate in DC, Maryland, Virginia, and Texas.

Experience

The founders of Capitol Flexi-Pave are degreed urban foresters with years of experience designing solutions for clients who desire to preserve natural resources within the limitations of a city environment. They have worked at numerous high profile and sensitive job sites including the White House, the Supreme Court of the United States, military bases, US Capitol Perimeter Security projects, the Library of Congress, and many other government and historical locations. Capitol Flexi-Pave provides the unique blend of experience with the superior qualities of the Flexi-Pave material. We bring that advantage to every project from individual homeowners to the largest government and city contracts. Please take the opportunity to learn more about this amazing product, its many applications, and its environmental benefits.

Can Flexi-Pave be installed onto the following materials?

- Wood: YES, The Urethane binding agent that is used penetrates the wood giving an immense grip.

- Steel: YES

- Aluminum: YES, The aluminum must be specially primed and then re-primed as per the installation manual.

- Concrete: YES

- Asphalt: YES

- Roofing Felt: YES

- Compacted Aggregate: YES, Crushed concrete, crushed asphalt, crushed marble are fine. Limestone products are not acceptable as they will become less porous over time.

- Enamel Tile: YES, The tile has to be acid-etched prior to priming.

- Fiberglass: YES, The fiberglass surface must be made coarse in finish and primed with flat primer.

Will Flexi-Pave crack?

NO – Because of the elastic properties.

Will Flexi-Pave have to be resealed because of ultraviolet light breakdown?

NO – Unlike two-part epoxy resins, the products are bound together with a single component urethane that has the same durometer as that of the rubber granule and which is totally resistant to UV degradation.

Will Flexi-Pave fade in time with exposure to the sun?

YES – Everything fades at certain speeds with continual exposure to sunlight and obviously at different speeds depending upon your location. Flexi-Pave has UV inhibitors in the colorization process therefore giving longevity to color-fastness.

Is Flexi-Pave porous?

YES – The products are manufactured using a nominal 3/8” rubber granule and this enables fast evacuation of water through its thickness because of the “open-pore” design.

Is Flexi-Pave flammable?

NO – Tire chips were tested in accordance with the Federal Hazardous Substance Act (16 CFR 1500.44) to determine whether tire material would be considered flammable (a material is considered flammable if it ignites and burns with a self-sustained flame at a rate greater than 0.1 inches per second along its major axis).

From the test results it was concluded that scrap tire material is considered a non-flammable.

Still have questions? Try our search box at the top of the page, or visit our contact page and ask us directly.

Is Flexi-Pave resistant to the following materials?

- Chlorine: YES

- Ozone: YES, for pools which use ozonation.

- Bromine: YES, for pools which use bromine instead of chlorine.

- Muriatic Acid: YES

- Salt Water: YES

- Oil: YES

- Transmission Fluid: YES

- Hydraulic Fluid: YES

Is Flexi-Pave slip-resistant?

YES – The surface is composed of thousands of rubber granules giving it incredible non-slip qualities.

How long does Flexi-Pave take to cure?

Under normal conditions it is recommended that a period of 24 hours be allowed for the Flexi-Pave to cure.

Can Flexi-Pave be installed in the rain?

NO – Flexi-Pave is a moisture-cured product, meaning if the product were mixed in the rain, the curing would be greatly sped up and cause the mixture to stiffen to the point of making it impossible to work with. Although we cannot install in the rain, we do use this “moisture curing” quality to our advantage and sometimes use a light spray of water after the Flexi-Pave has been installed in order to accelerate the curing process.

Does Flexi-Pave smell?

YES & NO – Only initially, similar to a new carpet having a smell. Once it has been installed for a few days, the smell goes away.

Do freeze-thaw conditions affect the integrity of Flexi-Pave?

NO – It is like one large and continuous expansion and contraction joint. Because of the elastic properties of the urethane and the compression capabilities of rubber, the pressure that is exerted by freezing water does not interfere with the mechanical strength of the products.

- Warranties

- Specifications

- Details

- Plan Room

- Operations and Maintenance

- Pre-Quals and Submittals

- Safety Testing

Standard 1 Year Warranty (complementary)

Capitol Flexi-Pave, LLC (CFP) warrants Flexi-Pave products for a period of one (1) year under the following terms: Flexi-Pave, when installed by CFP, will carry a warranty for materials for one-year from the date of installation. CFP’s warranty is limited to the structural and mechanical integrity of the installed Flexi-Pave materials. The warranty specifically EXCLUDES the following:

- Damage caused by intentional or unintentional abuse.

- Damage caused from the use of pressure cleaners or other abrasive devices.

- Damage caused by equipment usage on top without using a plywood covering. Prohibited equipment includes (Material Handlers, Skid Steers (tired or tracked), Bull Dozers, Mini-Excavators, Excavators, Graders, Tractors, Forklifts (warehouse-variety or Reach), Man Lifts (booms or scissors), Dumpsters & Roll-off containers, etc.

- Damage caused by any vehicle with the following tire types (knobby tires, off-road tires, equipment tires, solid tires, lug tread pattern tires, etc.)

- Damage caused by cranes, crane trucks or other lifting machines with or without outriggers

- Normal or abnormal wear & tear, such as surface stains, excessive vehicle wear and damage from lawn and garden equipment.

- Shade or color blend variations between the installed areas or between areas of installation performed at different times.

- Slight shade variations between products and samples or photographs.

- Imperfections commonly found in poured in place rubber products such as, sloughing, exposed aggregate, loose rubber granules and varying surface textures.

- Hairline cracks or separations between pours of less than ¼” width.

- Product porosity, base movement or sub-base movement.

- Alterations or modification to installed product (including, but not limited?to painting, speed bumps and tire stops).

Under such CFP limitations, any installation warranty shall be the responsibility of the original installer. CFP assumes no liability for installation costs of any kind. Imperfections in Flexi-Pave that do not affect the structural integrity of the engineered surface are not grounds for rejection or warranty claim.

Flexi-Pave is designed to “amber” in color as sunlight cures the proprietary binding agent. Fading over time is not grounds for rejection or warranty claim. As a result of usual methods of manufacturing recycled tire rubber granule, “cord” material is present in all Flexi-Pave products. The cord strengthens the overall structural integrity of Flexi-Pave and when installed properly, is not designed to create an absolutely smooth surface.

As a result of the Installation Process, small amounts of rubber granule and rock aggregate routinely slough off or become loose in the surface of the installed product. This condition is normal and is not grounds for rejection or warranty claim. The sloughing equates to the “New Carpet” phenomenon whereby small amounts of carpet fiber are commonly dislodged during the initial period of use.

Color or shade variations will be present in recycled rubber products and is an acceptable characteristic of Flexi-Pave. Flexi-Pave is manufactured using recycled tire and rock aggregate materials what will vary in size, shape, texture and color. CFP makes no warranty, whether expressed or implied, as to identical color matches. Color variations will occur in colored recycled tire products due to slight variations in dye lots and basic raw materials, as well as a result of after installation processes.

CFP’s warranty is limited to the cost of replacement product only and does not include any other costs, except as defined above. CFP does not guarantee that every color will be available perpetually in the future and if discontinued, CFP will provide an alternate color from its current product line at the time of an accepted warranty claim.

_______________________________________________________________________

Limited Lifetime Warranty (for a fee)

We at Capitol Solutions Group want your new porous pavement to last for a lifetime. That’s why Flexi-Pave is designed with durability in mind and is renowned for its permeability, recycled content, low cost of ownership and self-cleaning properties. Our industry standard 1-year warranty offers no-nonsense peace of mind, but with a little additional maintenance we can extend the warranty out indefinitely for the first owner to ensure its beauty and functionality for decades to come.

We recommend a cleaning and overspray once per year to reduce sloughing and reinforce surface integrity.

If you choose to follow our annual maintenance recommendations, you will receive a 1-year extension to the standard warranty. You may continue extending the warranty each subsequent year as long as you continue the maintenance recommendations. However, a lapse in maintenance will void the warranty extension program.

Items not covered under the warranty are mechanical damage, damage as a result of improper use, applied force beyond the stated or intended structural limitations of the product, operation of fork lifts, scissor lifts, man lifts, boom trucks, cranes, outrigger trucks, any solid tired equipment or any articulating / zero turn radius equipment, tracked equipment, pressure washers and force majeure. Repairs to the surface from these causes will be performed at a reduced rate for participants of the Warranty Extension Program. All others will pay standard rates for such repairs.

Need a Flexi-Pave Detail for your Construction Drawings? Feel free to peruse this assortment of Details and use any that meet your needs, or let us know the specific parameters of your project and we’ll make a custom Detail for you to use. Also don’t forget to download our CSI Masterformat Specs from the Specifications tab.

- 100.01.03 FLEXI-PAVE PARALLEL PARKING STRIP DETAIL REV3-1

- 101.01.02 FLEXI-PAVE RAISED DRIVEWAY WITH DRY STACK RETAINING WALL DETAIL-1

- 102.01.02 FLEXI-PAVE RAMP BETWEEN CONCRETE FLATWORK DETAIL rev2-1

- 103.01.01 FLEXI-PAVE SIDEWALK BETWEEN CURB & PLANTER DETAIL v1-1

- 104.01.00 FLEXI-PAVE COURTYARD BETWEEN BLDG & MOAT DETAIL-1

- 105.01.00 FLEXI-PAVE SERVICE ROAD WIDENING STRIP DETAIL-1

- 106.01.01 FLEXI-PAVE PARKING STALL DIFFUSION STRIP DETAIL V1-1

- 107.01.01 FLEXI-PAVE DRIVEWAY DETAIL v1-1

- 108.02.01 FLEXI-PAVE ABOVE GRADE DRIVEWAY DETAIL HOW TO-1

- 109.01.00 FLEXI-PAVE MEDIAN BETWEEN CURB & PLANTER DETAIL-1

- 110.01.00 FLEXI-PAVE PAVEMENT SECTION WITH 6 INCH UNDERDRAIN DETAIL-1

- 111.01.00 FLEXI-PAVE MEDIAN BETWEEN CURB & SEAT WALL DETAIL-1

- 112.01.00 FLEXI-STONE RAISED DRIVEWAY DETAIL-1

- 113.00.00 FLEXI-PAVE SIDEWALK DETAIL-1.

- 114.00.00 FLEXI-PAVE TRAIL OVER CRZ DETAIL-1

- 115.00.00 FLEXI-PAVE DRIVEWAY WITH UNDERDRAIN DETAIL-1

- 116.01.00 FLEXI-PAVE DRIVEWAY WITH UNDERDRAIN DETAIL 2-1

- 117.00.00 FLEXI-PAVE FIRE ACCESS LANE DETAIL

- 118.00.00 FLEXI-PAVE SIDEWALK DETAIL

- 119.00.00 FLEXI-PAVE TRAIL @ CLOSED KLINGLE

- 120.00.00 FLEXI-PAVE FLUSH TRAIL @ CLOSED KLINGLE

- 121.00.00 FLEXI-PAVE TREE SURROUND DETAIL

- 123.00.00 FLEXI-PAVE BIKE SHARE DETAIL

- 124.00.00 FLEXI-PAVE TREE SURROUND FOR SMALL TREES DETAIL

- 125.00.00 FLEXI-PAVE TREE SURROUND FOR SMALL TREES DETAIL

- 126.00.00 FLEXI-PAVE TREE SURROUND FOR SMALL TREES DETAIL

- 127.00.00 FLEXI-PAVE TREE SURROUND FOR SMALL TREES DETAIL

- 128.00.00 FLEXI-CURB FOR PERMEABLE SOIL DETAIL

- 129.00.00 FLEXI-CURB FOR NON-PERMEABLE SOIL DETAIL

- 131.00.02 FLEXI-PAVE TREE SURROUND – AMERICANS DISABLED FOR LIFE MEMORIAL 6-17-14 REV2

- 132.00.00 FLEXI-PAVE ANCHORING FOR BENCHES, TABLES, TRASH RECEPTICLES 12-9-14.pub

- 133.00.00 FLEXI-STONE TREE SURROUND FOR NEWLY PLANTED TREES 6-11-15

- 134.00.00 FLEXI-PAVE TREE SURROUND FOR NEWLY PLANTED TREES 6-12-15.pub

- 135.00.00 FLEXI-PAVE TRAIL FLUSH WITH GRADE 7-2-15

- 136.00.00 FLEXI-PAVE ABOVE GRADE DRIVEWAY STRIPS DETAIL 9-16-15

- 137.00.00 FLEXI-PAVE TRAIL IN WETLAND DETAIL

- 138.00.00 FLEXI-STONE EXTREME FSX2000 POROUS VEHICULAR PAVEMENT DETAIL

- 139.00.00 FLEXI-PAVE TRAIL WITH TURNDOWN EDGES OVER HARDENED LAVA DETAIL

- 140.00.00 FLEXI-PAVE FOUNTAIN GRATES DETAIL

- 141.00.00 FLEXI-PAVE WITH BREAK-AWAY RING FOR NEWLY PLANTED TREES 12-11-15

- 142.00.00 FLEXI-STONE PARKING LOT DETAIL

- 143.00.00 FLEXI-STONE DRIVEWAY DETAIL

- 144.00.00 FLEXI-PAVE DIFFUSION STRIP WITH UNDERDRAINS DETAIL

- 145.00.00 ALL-STONE DRIVEWAY DETAIL

- 146.00.00 P2000 PLAYGROUND DETAIL

- 147.00.00 FLEXI PAVE DRIVEWAY OVER CRZ DETAIL

- 148.00.00 FLEXI PAVE PARKING SPACE DETAIL

- 149.00.00 FLEXI PAVE SPORT COURT DETAIL

- 150.01.00 FLEXI PAVE OVER ROOT DETAIL

- 151.00.00 POUR STOP DETAIL

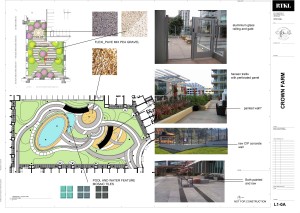

Are you a design professional? Do you need more LEED points on your projects? Do you need to eliminate more impervious surfaces from your designs? Are you curious how other Landscape Architects, Architects & Engineers are incorporating Flexi-Pave into their projects? Look no further. We have assembled resources for you to view a sampling of projects of various size in the area that we have built in the last few years. Feel free to explore these plans & details to see what other professionals are doing to stay ahead of the curve.

RRP2_ VA POWER PATH 10TH SCALE

FORT WARD PARK-Bastion Walkway Project SHT2

Flexi-Pave blow up plan

Flexi-Pave Stormwater Mgmt Plan

7th from Kearny to Hamlin NE

14th at Underwood NW

1600 Michigan Ave NE

Bunker Hill from 22nd to 24th NE

Georgia Ave at Fern St NW-1

Albemarle at Fort NW

Albemarle from Wisconsin to Fort NW

Eastern at Perry NE

2nd St. at E St. NW-1001000

6th & E street SW

17th & A St SE 1

17th & A St SE 2

300 Pensylvannia Ave SE

2017 37TH NW

Butternut St. from Piney Branch to 6th St. NW

Columbia & 19th_Sheet1

Connecticut Ave at Cumberland St. NW-1002535&1002539

Rhode Island from 7th to New Jersey NW

Green-Alleys-Chevy-Chase_22x34_ADV_plans signed

54-69 ARCH

70-79 STREET DETAILS

Sajadi Driveway Plan 10-21-2013 v2

L2-34-1.07.2 LEVEL 12 ROOF TERRACE (PARCEL 3)-DOG PARK MATERIAL-PLANTING PLAN – Flexi-Pave Plan

L2-34-1.07.3 LEVEL 12 ROOF TERRACE (PARCEL 3)-DOG PARK LAYOUT PLAN – Flexi-Pave Plan

7811 site plans

Landy & River

PR_35 Cross Slope Path

Flexi-Pave

515-14 GCAF DRAWING SET

Approved Sediment Control Plan Bethesda Mews_246611 112913

5333CT-LABase-rev-drop-off 131025

Overlook Ats 2012-12-12_1of4-Maintenance

L2.3 – HARDSCAPE CONSTRUCTION PLAN – LEVEL 5 – BULLETIN 4 – 02.06.12

L3.1.2 – HARDSCAPE CONSTRUCTION DETAILS – ROOFTOP DOG RUN – BULLETIN 4 – 02.06.12

Sheet 3_Materials Plan

Sheet 16_Details

A2.7 – LEVEL 5 FLOOR PLAN – RESIDENTIAL – BULLETIN 4 – 02.06.12

L1.00_BULLETIN_38

Topography:Landscape Diagram for SML lot

Flexi Pave Detail

Flexi Pave

LC-1_Layout and Materials Plan

LK-1_Details

Sheet 3_Materials Plan

Sheet 16_Details

SHT 06 – MATERIALS PLAN MARKED UP

SHT 26 – DETAILS

Extract Pages From Horizontal Maine Avenue Landscaping Drawings 2013-01-25 main ave composite flexipave map

Extract Pages From Horizontal Maine Avenue Landscaping Drawings 2013-01-25 flexipave sidewalk detail

L203.0 MATERIALS PLAN – PENNSYLVANIA AVE

L001

L302(1)

RRP2_ BASE_LABYRINTH SHEET L-1 2013.08.29

GC-AF-FLEXIPAVE 2013.07.19

L0.0-L2.0_WoodLawnPark_08-23-2013 marked up 9-11-13

Armistead_Booth_Park_Drawings DETAIL SHEET MARKED UP 11-16-13

Armistead_Booth_Park_Drawings_Pgs_1-9 marked up

SHT 4 – Layout Sheet Marked up 10-22-12

SHT 12 – Details Sheet Marked up 10-22-12

Extract Pages From Drawing – Brookside CS1 CS2

ANC Sidewalk Phasing Plan 9-29-11 V2

ANC_Detail Sheet_1_20130603_updated_06262013 marked up 8-21-13

ANC_Drawings_1_20130603_updated_06262013 marked up 8-21-13

Site Plan

Kennedy Rec Center Plan

Hadley Driveway Plan Marked up 1-2-12

Edgewood Terrace Details marked up 8-20-13 V1

Edgewood Terrace plan marked up 8-19-13 Rev1

C-101

C-102

1230_PLOT_L2.02 DETAIL SITE PLAN

1230_PLOT_L3.01 SITE DETAILS

1230_PLOT_L4.01 SECTIONS

TUCKAHOE REBID 120921 PART 3 OF 4 marked up 7-19-13

Parkside Block E L-111 – Flexi-Pave Locations marked up 8-21-13 v2

Long Bridge Aquatic Center Details Sheet Marked up 12-18-13

Long Bridge Aquatic Center Plan 2 Marked up 12-18-13

Long Bridge Aquatic Center Plan Marked up 12-18-13

RR-7 Marked up Plan 9-18-12

RR-19 Details Sheet Marked up 9-18-12

EW-LA BASE 1-20scale (1)

USNA Herb Garden Renovations_FULL SIZE marked up 8-15-13

L-101a marked up 4-29-13

Simon Playground (Design Development Set 02-28-2013) Marked up 4-2-13 Rev3

flexi-pave

Meade & Arlington 11-11-21

Veitch & 20th 11-11-21

C-08 Marked up 7-17-12

DSP2004-00038 (4)[1]

Ballfields Bid Documents 2_27_2012 marked up plans 4-6-12

CCDC_DOG PARK_08.31.2012._for Noblepdf

CCDC_DOG PARK_09.10.2012_MOUND_plexipave

CCDC_RT_DOG PARK_121205

Site Plan Amendment 2011-10-11 with measurements

Enlargements for Flexi-Stone Marked up

Flexi-Stone Paving Section

Site Plan for Flexi-stone

Al Hibri Driveway Markup

Flexible Paving

L5.20_BULLETIN_1

TJB L101

TUCKAHOE REBID 120921 PART 3 OF 4 marked up 7-19-13

The Following topics are covered here:

- Resources for Operations & Maintenance Procedures v7.5

- Operational Guidelines

- Flexi-Pave/Flexi-Stone Surface Protection Procedure

- Flexi-Stone Hairline Crack Potential

- Flexi-Pave Tree Surround Maintenance Procedure

Resources for Operations & Maintenance Procedures v7.5

PX3000, P3000 (3″ – 75mm)

HD2000, HDX2000, PX2000, P2000, FS2000 (2″ – 50mm)

HD1500, HDX1500, PX1500, P1500 (1 1/2″ – 37.5mm)

HD1000, HDX1000, PX1000, P1000 (1″ – 25mm)

FS500 (1/2″ – 12.5mm)

Flexi-Pave’s flagship products, HDX2000, HD2000, HD1500 & HD1000 are made of 50% 3/8” crumb recycled tires and 50% 3/8”-½” granite chips, held together with an elastomeric polyurethane binder XP-75. Flexi-Pave’s all rubber surfaces, P3000, P2000, P1000 and PX2000 are made of 100% ?” crumb recycled tires and an elastomeric polyurethane binder XP-75 or XP-35. Flexi-Stone, FS2000 & FS500 are made of a 100% washed ¼”-1/8” gravel overlay approximately ½” deep which is poured on top of standard HD2000 or HD1500 Flexi-Pave using the XP-75 Urethane Binder. Once cured, the all the products maintain approximately 19-23% internal pore space, which gives them a pervious rating of nearly 4000 inches of water per hour (over 2500 gallons per square foot per hour). Therefore Flexi-Pave is essentially “invisible” to storm water runoff making it an ideal solution for many paving situations.

Unlike other porous paving materials, which have static internal voids and require routine vacuuming to maintain porosity, Flexi-Pave’s internal pore capacity is dynamic in nature. Due to the Flexi-Pave’s inherent flexible properties the internal pores change size & shape during loading, thermal expansion and use, thus allowing particulates to be broken down into smaller and smaller pieces and finally passing through the paving into the #57 stone base course. As such, Flexi-Pave does not typically require vacuuming and is considered for the most part, “self-cleaning”. Therefore standard cleaning and maintenance recommendations are kept to a minimum and are listed below:

Operational Guidelines:

- It is recommended that routine street maintenance be carried out in accordance with maintenance best practices. This will ensure continual performance of Flexi-Pave.

- It is recommended that if Flexi-Pave endures foliage surface debris (i.e. leaves, grass clippings, etc.) that the debris be blown off periodically. This will prevent the natural compost material from forming, accumulating and decaying within the Flexi-Pave so as to not promote the growth of plant seeds, or weeds.

- We recommend that if the Flexi-Pave is installed adjacent to any loose aggregates used for paving or landscape, that the loose aggregate be blown off periodically. This will prevent any unnecessary surface aggravation or friction from vehicular or foot traffic that could harm the surface integrity of Flexi-Pave.

- In the event that the surface of Flexi-Pave becomes clogged with fine dirt or sand, copious amounts of water should be applied at low pressure using a garden hose or similar hose design. This will wash through and displace the loose fines.

- On rare occasions where considerable slit loading may occur, i.e. “Excessive Sand Loading”, a common street sweeper or vacuum can be used to extract the excess fines.

- DO NOT use pressure cleaners on the surface

- DO NOT use abrasive devices such as sweepers on the surface

- DO NOT use heavy equipment on paving surface without covering surface with plywood first. (Prohibited equipment on Flexi-Pave includes Material Handlers, Skid Steers (tired or tracked), Bull Dozers, Mini-Excavators, Excavators, Graders, Tractors, Forklifts (warehouse-variety or Reach), Man Lifts (booms or scissors), Dumpsters & Roll-off containers, etc. Also, any vehicle with the following tire types is prohibited including knobby tires, off-road tires, equipment tires, solid tires, lug tread pattern tires, etc.

- Do NOT use cranes, crane trucks or other lifting machines with outriggers on the surface

- For de-icing, use standard rock salt

- For snow removal, use standard show shovels or light pneumatic tired snow plows with a rubber spacer on the blade to protect the surface, or raise the plow just above the surface.

- When operating light vehicular traffic on the surface, DO NOT turn the wheels without the vehicle being in motion. Static turns of rubber tires on a porous rubber surface cause excess friction and can dislodge rubber granules and aggregate on the surface.

- If imperfections appear in the surface texture such as exposed aggregate and loose rubber granules which are commonly found in poured-in-place rubber products these can be blown off with a standard leaf blower. This condition is known as sloughing and does not affect the functionality or durability of the product.

- As a preventative practice to prevent sloughing, an overspray of the XP-75 of XP-35 binder can be applied (for a nominal additional fee) to the surface on an annual basis if desired. The overspray does not affect the permeability of the product, but serves to re-adhere any loose granules and reconstitute the surface.

Data is based on facts that we believe to be accurate but all recommendations are made without warranty since conditions of use are beyond Capitol Flexi-Pave’s control. We do not assume any liability except what is expressly noted in the warranty certificate. We do not assume any liability from injury resulting from use. Liability, if any, is limited to replacement of product.

END OF SECTION

Flexi-Pave / Flexi-Stone Surface Protection Procedure

All porous surfaces have restrictions on their use such as man lifts, forklifts, tracked vehicles, etc. In addition, when performing construction activities on or near Flexi-Pave, or placing temporary exhibits, equipment or tents on the surface, certain precautions must be taken to prevent damage to the surface:

- Cover Flexi-Pave with poly sheeting to collect loose stone dust, sand, or other granular materials that may be dislodged during adjacent construction activities.

- Cover Flexi-Pave with plywood path prior to traversing it with any vehicle or piece of equipment other than a pneumatic rubber tired passenger vehicle.

- Cover Flexi-Pave with plywood prior to traversing it with a vehicle with muddy tires.

- Prior to installing concrete ballast blocks, concrete fence panel footings, or tent posts, protect Flexi-Pave with plywood pieces directly under the areas that may become scuffed.

- For Flexi-Stone in particular, do not drop dense heavy items such as concrete on the surface or the gravel pieces in the Flexi-Stone surface may become crushed and/or dislodged at impact.

END OF SECTION

Flexi-Stone Hairline Crack Potential

Flexi-Stone FS2000 or FS500 is made of a washed ¼”-1/8” gravel overlay approximately ½” deep which is poured on top of standard HD1500 or HD2000 Flexi-Pave using the XP-75 Urethane Binder. Standard HD2000 is made of 50% 3/8” crumb recycled tires and 50% 3/8”-½” granite chips, but FS2000 and FS500 lacks the rubber component. The rubber component provides flexibility and so the FS2000 or FS500 products are inherently less flexible than the HD2000 product. And since Flexi-Stone is poured in monolithic type pours without expansion joints, there is a potential for hairline cracks to appear in the top-coat Flexi-Stone veneer during the break-in period after an installation (similar to hairline cracks in concrete). This may occur if the ground, sub-base or base course moves, shifts or settles. The Flexi-pave rubberized base is able to bend with a moving base, however the Flexi-Stone veneer is not as flexible. Any hairline cracks that appear will not hinder the functionality or porosity of the product. Hairline cracks will not extend into the underlying HD2000 Flexi-Pave base. Therefore they are deemed inconsequential to the product’s durability and within acceptable limits of the manufacturers tolerances for this product. Hence, hairline cracks in the Flexi-Stone surface do not constitute a warranty claim on the product unless they extend more than ¼” in width, at which point they will be repaired for free within the warranty period.

No repair procedure is required for hairline cracks under ¼” in width. However, hairline cracks over ¼” in width can be repaired though the following procedures:

- Identify the source and terminus of significant observable cracks over ¼” width.

- Using chisel & hammer, chip away a furrow along the crack to expose a 1” wide by ½” deep crevice.

- Clean the crevice of loose gravel and dust.

- Using a chip brush, apply XP-75 binder to the sides and bottom of the crevice.

- Mix an adequate quantity of Flexi-Stone with XP-75 binder according to the manufactures directions.

- Fill the crevice with the rock/binder mixture.

- Smooth the surface with hand trowels.

- Optional: Apply additional coat of XP-75 binder to the top of the repair.

- Allow curing period of 24 hours to achieve full hardness. (72 hours in winter)

- As with all natural stone products, minor variations of Flexi-Stone color may remain observable until full UV curing period. Allow several months for color of patch to more closely resemble color of surrounding surface.

END OF SECTION

Flexi-Pave Tree Surround Maintenance Procedures

Flexi-Pave tree surrounds represent an excellent solution for urban tree pits. They are made of HD2000, PX2000 or P2000. Flexi-tree surrounds are typically used when sidewalk space is limited and/or the desire is to maximize walkable space for pedestrians or to reduce soil compaction, eliminate trash collection in tree pits or to reduce overall maintenance requirements.

When sidewalks are adequately wide enough, (ADA requires at least 4’ width of the travel path) the standard procedure is to leave an open box around the tree trunk with soil and mulch, then pave the adjacent sidewalk with Flexi-Pave. These types of sidewalk known as “Treewalks” represent the best, longest lasting and easiest to maintain solutions available for urban tree/sidewalk interfaces.

But when space is limited, when tripping hazards exist or when constant foot traffic is causing compacted soils and tree mortality, Flexi-Pave tree surrounds are optimal. The benefits of Flexi-Pave tree surrounds, include the following:

- Eliminating tripping hazards & providing an ADA compliant spaces

- Increasing walkable space for narrow sidewalks

- Reducing maintenance requirements

- Preventing soil compaction

- Allowing water and oxygen infiltration into soil rhizosphere

- Moderating soil temperatures

- Improving overall tree health

- Preventing trash accumulation in tree pits

- Discouraging rodent infestations in tree pits

- Maintaining flexibility as tree roots & trunks grow

As trees are living, constantly changing organisms, the inherent flexible properties of Flexi-Pave are especially beneficial. Flexi-Pave is able to bend and flex as tree trunks and root flares grow. Therefore Flexi-Pave resists breaking when traditional impervious surfaces like asphalt and concrete cannot bend, and thus crack or break causing trip hazards and ADA violations.

Depending on tree trunk caliper, Flexi-pave tree surrounds are installed using three primary methods while allowing for certain modifications as site conditions and objectives require. The three primary methods used for tree surrounds are as follows:

Large trees (>12” caliper): Flexi-Pave is installed in the entire tree box at 2” nominal depth all the way up to the tree trunk. Trees in this size class typically maintain the ability to “self-prune” the Flexi-pave tree trunk opening as their trunks grow and caliper increases. The individual Flexi-pave rubber and stone granules are able to be broken off one by one over time as the tree puts pressure on them, and they are lost to the environment. Should a bulge of bending Flexi-Pave be seen at the tree trunk/flexi-pave interface, the excess material can be chipped away to relieve the bulge pressure using the “Trunk hole enlarging procedure” outlined below.

Medium trees (6-12” caliper): Flexi-Pave is installed at a 2” nominal depth except within an 18” diameter of the tree trunk, where the flexi-pave is installed at a 1” depth on top of a 1” layer of loose dry rubber granule. This in continued to within 6” of the tree trunk and the final 6” is left open, or filled with dry loose rubber granule. This method provides an opening and then thinner section of Flexi-Pave around the tree trunk making it easier for the medium sized trees to “self-enlarge” the tree trunk hole as the grow in circumference. As the tree grows, the individual Flexi-pave rubber and stone granules are broken off and they are lost to the environment. Should a bulge of bending Flexi-Pave ever be seen at the tree trunk/flexi-pave interface, the excess material can be chipped away to relieve the bulge pressure using the “Trunk hole enlarging procedure” outlined below.

Small trees (1-5” caliper): Newly planted trees face a greater chance of mortality during the first few years of establishment and therefore a contingency plan for their replacement must be factored in. For small trees in this class, Flexi-pave is installed at a 2” nominal depth to within 6”-12” from the edge of the outside of the original root ball. Then a sacrificial “break-a-way ring” of Flexi-pave is poured all the way up to the tree trunk. The break-a-way Flexi-pave ring is comprised of a ½” depth of Flexi-pave installed over a 1.5” deep bed of loose dry rubber granule. At the tree trunk, a 6’ diameter hole is left open and this void can be filled with loose rubber granule, Flexi-Mulch, or left open. A steel or composite landscape edging is installed flush with the top of pavement as a bond breaker between the 2” deep Flexi-Pave and the break-a-way ring. As the tree trunk grows and self-enlarges the trunk hole of the break-a-way ring nothing is typically required for maintenance. This method provides the thinnest section of Flexi-Pave around the tree trunk making it easier for the small trees to self-enlarge the tree trunk hole. The individual Flexi-pave rubber and stone granules are broken off over time as the tree puts pressure on them, and they are lost to the environment. Should a bulge of bending Flexi-Pave ever be seen at the tree trunk/flexi-pave interface, the excess material can be chipped away to relieve the bulge pressure using the “Trunk hole enlarging procedure” outlined below. In the event that the tree dies, the entire sacrificial break-a-way ring of Flexi-pave can be removed back to the landscape edging bond breaker. (Plastic sheeting, geotextile fabric or plywood should be used to protect the porous Flexi-pave surface prior to a dead tree removal and tree replanting.) Once the sacrificial break-a-way Flexi-pave ring is removed, the tree can be extracted and replaced with a new tree. Dispose of the sacrificial break-a-way ring of Flexi-pave. Then re-pour a new interior break-a-way ring of Flexi-pave. Alternatively the open space can be left open or filled with mulch, loose rubber granule or Flexi-Mulch.

In our constant progression we are always seeking better means, methods and materials for our tree and pavement solutions, therefore in an effort to improve our service line, we reserve the right to modify our services or procedures with or without notice as our research and development determines.

END OF SECTION

Flexi-Pave Tree Surround Trunk Hole Enlarging Procedure

Tools needed – Flathead screwdriver or chisel, hammer & trash bag

Time needed – Approximately 5-15 minutes per tree

- Identify trees with significant bulges in the Flexi-pave where it contacts the tree trunks

- Using the hammer and screwdriver carefully chisel a 1” to 6” wide ring around the tree trunk

- Break off and discard the excess pieces of Flexi-pave

In our constant progression we are always seeking better means, methods and materials for our tree and pavement solutions, therefore in an effort to improve our service line, we reserve the right to modify our services or procedures with or without notice as our research and development determines.

END OF SECTION

If you are a General Contractor in need of our pre-quals and submittals for a project startup we have everything you need here. Download the the specific items that the Specs on your project require. The standard requirements are the Mix Design, Manufacturer’s Certification, Color Palette and Company Bio. But some projects require additional items. We look forward to working with you.

Standard Submittals:

Additional Submittals:

At Capitol Solutions Group, we provide products that are environmentally safe, address important challenges, and increase quality of life in our communities. We, therefore, turn to science to ensure we are meeting those standards. The EPA has cited numerous scientific studies that address concerns over the possibility of toxic substances associated with synthetic turf fields or playgrounds using crumb rubber from recycled tires, and all of them conclude that detectable levels are so far below acceptable thresholds that there is negligible to no increased health risks to humans or the environment.

- A Scoping Level Field Monitoring Study of Synthetic Turf Fields and Playgrounds

- Artificial Turf Pitches – An Assessment of the Health Risks for Football Players | NIPH 2006

- CDPH Human Health Risk Assessment of Turf Fields Based Upon Results from Five Fields Connecticut 2012

- CPSC Analysis and Assessment of Synthetic Turf Grass Blades 2008

- Federal Research Action Plan on Recycled Tire Crumb Used on Playing Fields and Playgrounds 2016

- NYC Air Quality Survey of Synthetic Turf Fields Containing Crumb Rubber Infill 2009

- NYC A Review of the Potential Health and Safety Risks from Synthetic Turf Fields Containing Crumb Rubber Infill 2008

- NYSDEC 2009 – An Assessment of Chemical Leaching, Releases to Air and Temperature at Crumb-Rubber Infilled Synthetic Turf Fields

- OEHHA 2007 Evaluation of Health Effects of Recycled Waste Tires in Playground and Track Products

- Preliminary Assessment of the Toxicity from Exposure to Crumb Rubber: Its Use in Playground and Artificial Turf Playing Fields 2007

- Field Study of Water Quality Effects of Tire Shreds Placed Below the Water Table